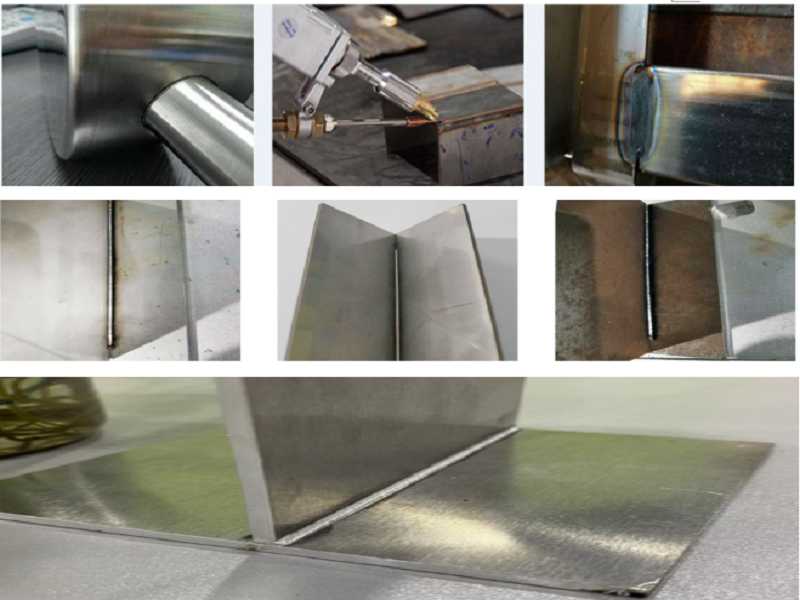

The laser handheld welding machine uses a handheld welding torch to replace the previously fixed optical path, subverting the previous working mode of the laser welding machine. This operation mode is not only convenient for welding of molds, advertising characters, kitchenware and other products, but also for outdoor laser welding. The handheld torch operating mode enables the workpiece to be welded at any position and at any angle.Suitable for welding of various complex shapes and spot welding of various equipment. Application range:Widely used in kitchens, household appliances, advertising, molds, stainless steel doors and windows, crafts, household goods, furniture, auto parts and many other industries.

vivian@hanstarmachine.com Feedback

Application:

The laser handheld welding machine uses a handheld welding torch to

replace the previously fixed optical path, subverting the previous

working mode of the laser welding machine. This operation mode is not

only convenient for welding of molds, advertising characters,

kitchenware and other products, but also for outdoor laser welding.

The handheld torch operating mode enables the workpiece to be welded at

any position and at any angle.Suitable for welding of various complex

shapes and spot welding of various equipment.

Application range:Widely used in kitchens, household appliances,

advertising, molds, stainless steel doors and windows, crafts, household

goods, furniture, auto parts and many other industries.

Technical Parameters

| Model | Hand Held Laser Welding Machine |

| Machine out dimension | 680*1160*940(mm) |

| Laser source | 500-1500W RAYCUS |

| Welding head | OSPRI |

| Water chiller | 2Pchiller ·double control |

| Control | Industrial PLC |

| Power | 220V single 50Hz |

| Power in total | 5000W |

| Max speed | 20m/min(According to the thickness ) |

| Cooling way | water cooling |

| Laser wavelength | 1070nm |

| Continuous working time | 24 Hours |