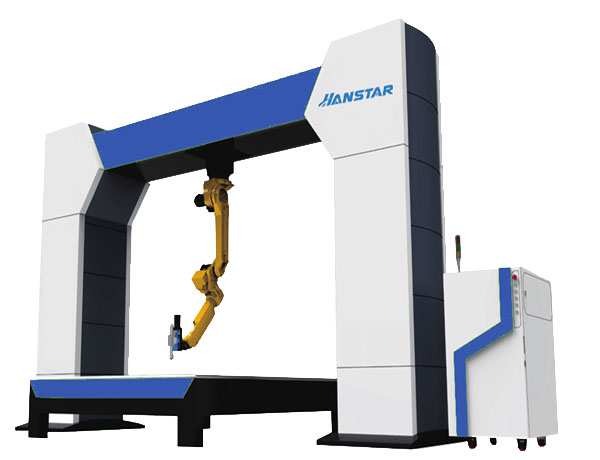

Robot laser cutting machine is mainly for 3D precision laser processing of large size parts. The machine tool has a gantry structure and the beam moves; the three-dimensional head can realize n × 360 ° infinite rotation and ± 135 ° swing. From cutting to welding, the processing head can be quickly replaced without adjustment, and one machine can be used for two purposes. The fiber laser is particularly suitable The laser cutting of aluminum alloy and titanium alloy in the industry can choose the size of the robot according to the different needs of customers.

vivian@hanstarmachine.com Feedback

| NO. | Project | Specifications and grades |

| 1 | Robot | YASKAWA/KUKA (OPTIONAL ) |

| 2 | Laser source | IPG(1.0W~6KW) |

| 3 | Control system |

SIEMENS S7-1200 KUKA-KR30H Robot controller |

| 4 | Z axis servo system | Raytool |

| 5 | Laser cutting head | Raytool/Precitec |

| 6 | Air distribution system | air compressor, cold dry machine, filter |

| 7 | Protective light curtain | Length 500 super wing Electronics |

| 8 | Voltage stabilizer | Baowen |

| 9 | Max. Loading Weight | 28kg |

| 10 | Arm Length | 2010mm |

| 11 | Axis Quantity | 6 |

| 12 | Working fiber | Core diameter 0.2mm,length 20m |

| 13 | Min. hole diameter | 3mm |

| 14 | Repeated Accuracy | ±0.03mm |