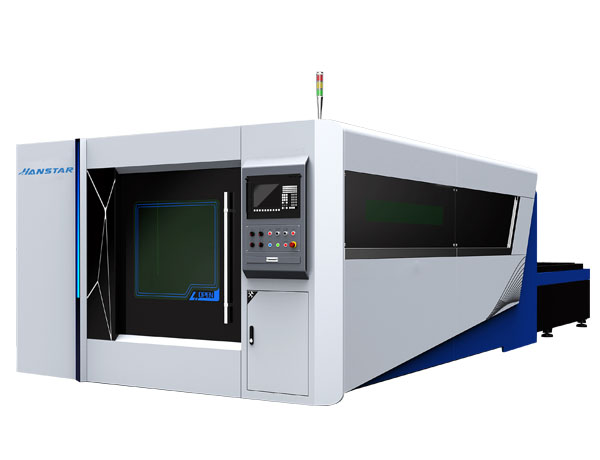

Applicable Industries:Railway transportation, ship building, automobile, construction machinery, agroforestry machinery, electrical manufacturing, elevator manufacturing, household applications, food machinery, textile machinery, tool processing, petroleum machinery, kitchenware and bathroom, decorative advertising, laser processing service etc. Cutting Materials: can be cut: Mild steel, stainless steel, aluminum alloy, brass, copper, pickling plate, galvanized plate, silicon steel, electrolytic plate, titanium alloy, manganese alloy.

vivian@hanstarmachine.com Feedback

Applicable Industries:Railway

transportation, ship building, automobile, construction machinery,

agroforestry machinery, electrical manufacturing, elevator

manufacturing, household applications, food machinery, textile

machinery, tool processing, petroleum machinery, kitchenware and

bathroom, decorative advertising, laser processing service etc.

Cutting Materials: can

be cut: Mild steel, stainless steel, aluminum alloy, brass, copper,

pickling plate, galvanized plate, silicon steel, electrolytic plate,

titanium alloy, manganese alloy.

| Machine Model Optional | HSF-3015H/4015H/6015H/4020H/6020H |

| Cutting size optional(mm) | 3000x1500/4000x1500/6000X1500/4000x2000/6000x2000 |

| Laser source | Fiber Laser |

| Laser power Optional | 1000W-6000w |

| Z axle stroke | 276 mm |

| Max positioning speed | 180m/min |

| Maximum acceleration | 1.0G |

| Max height of feeding material | more than 120mm |

| Cooling way | water cooling |

| Laser wavelength | 1070nm |

| Min. cutting gap | ≤0.1mm |

| Positioning accuracy of X, Y and Z axles | ±0.03 mm |

| Repeated positioning accuracy of X Y Z axles | ±0.01 mm |

| Working temperature | 5℃-45℃ |

| Power requirement | 380V,50/60Hz(customized for you) |

| Continuous working time | 24 Hours |

| Machine weight in total | 21 tons |

| Machine positioning accuracy | ±0.03mm/m |

| Edge detection accuracy | ±0.5 |

| Rated input voltage | 380V±10% |